TOWER SYSTEM – set-up at Maker Faire 2014 May 22, 2014

Posted by rik94566 in adafruit, agponics.com, arduino, DIY aquaponics, DS18B20, Electronic Componets, indoor aquaponics, indoor gardens, indoor growing, Internet-of-Farming, IoT aquaponics, One-wire, Raspberry PI, Tower System, Tower Tubes.Tags: agponics, aquaponics, automation, Controlled Environment Agriculture, DIY aquaponics, indoor aquaponics, IoT, Maker Faire, microcontroller, rik kretzinger, sensor

2 comments

EDITOR’S CHOICE – not once – but 3 times @ Maker Faire – WOW May 21, 2014

Posted by rik94566 in agponics.com, aquaponic automation, aquaponics, aquaponics electronics, arduino, DIY aquaponics, indoor aquaponics, indoor gardens, indoor growing, Internet-of-Farming, IoT aquaponics, Raspberry PI, sensor, Tower System.Tags: aquaponic automation, aquaponics, automation, DIY aquaponics, indoor aquaponics, microcontroller, rik kretzinger

2 comments

Very few displays achieve 3 EDITOR CHOICE AWARDS —

RADIAL FLOW FILTER – just completed April 2, 2014

Posted by rik94566 in agponics.com, aquaponic automation, aquaponics, aquaponics electronics, Controlled Environment Agriculture, DIY aquaponics, Electronic Componets, indoor aquaponics, Internet-of-Farming, IoT aquaponics, PRODUCTS, radial flow filter, Tower System.Tags: aquaponic automation, automation, Controlled Environment Agriculture, DIY aquaponics, indoors aquaponics, IoT, microcontroller, rik kretzinger

add a comment

Since first conceiving of the Tower unit as a concept I knew they needed to be operated differently than DWC and Media bed in how you deal with the solids from the fish. Media beds — it has not been that big a deal for me because my rule is that any tank size smaller than 350 I filter the water and break-up the solids and then put back into solution by pumping back into the grow beds. This way I lose no nutrients that the fish produce. Has worked well for over 3 years now. In the testing that I have done with the towers I found that solids need to be dealt with or things will plug up. I still will be reintroducing the broken up solids back into the system put it will take place downstream of the bio-filter component and re-injected into the new buffer tank that stabilizes fish tank water volume and height. This all came out of research I was doing on how best to handle solids in aquaponics. As designed this radial flow filter can handle up to and maybe a bit more than a 1000 gallons of fish tank water. The only thing left to figure out on this radial flow filter now is where I will be locating the outlet for the clean water. That will be dependent on fish tank water level. Should have fish tank completed this coming weekend and make the determination on this aspect of the build.

Since first conceiving of the Tower unit as a concept I knew they needed to be operated differently than DWC and Media bed in how you deal with the solids from the fish. Media beds — it has not been that big a deal for me because my rule is that any tank size smaller than 350 I filter the water and break-up the solids and then put back into solution by pumping back into the grow beds. This way I lose no nutrients that the fish produce. Has worked well for over 3 years now. In the testing that I have done with the towers I found that solids need to be dealt with or things will plug up. I still will be reintroducing the broken up solids back into the system put it will take place downstream of the bio-filter component and re-injected into the new buffer tank that stabilizes fish tank water volume and height. This all came out of research I was doing on how best to handle solids in aquaponics. As designed this radial flow filter can handle up to and maybe a bit more than a 1000 gallons of fish tank water. The only thing left to figure out on this radial flow filter now is where I will be locating the outlet for the clean water. That will be dependent on fish tank water level. Should have fish tank completed this coming weekend and make the determination on this aspect of the build.

I put together a youtube slide show if you want to see more detail of the radial flow filter:

200,000 Views on Youtube – “Internet of Farming” — WOW February 2, 2014

Posted by rik94566 in agponics.com, aquaponic automation, aquaponics, Crop, DIY aquaponics, Internet-of-Farming, IoT aquaponics, Tower System.Tags: aquaponic crop, automation, Controlled Environment Agriculture, DIY aquaponics, indoor aquaponics, IoT, LED aquaponics, microcontroller, rik kretzinger, Temp Probe, Temperature Probe

add a comment

SENSOR COLOR CODE – for tracking where the probes are in the towers December 9, 2013

Posted by rik94566 in agponics.com, aquaponic automation, aquaponics, Controlled Environment Agriculture, DIY aquaponics, DS18B20, IoT aquaponics, Tower System, Tower Tubes.Tags: aquaponic automation, aquaponic crop, DIY aquaponics, rik kretzinger, sensor

2 comments

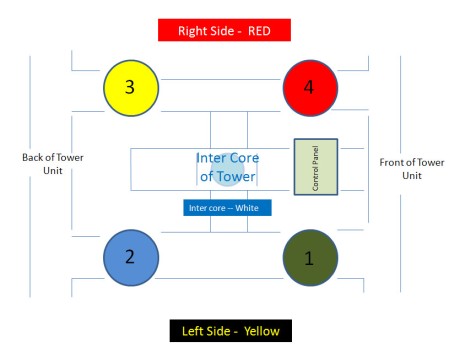

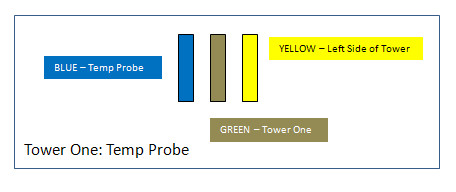

Since I have a larger number of sensors in each tower unit I needed a way to know the exact sensor I will be dealing with and the location of the sensor. The best way for me is to mimic the electronic color codes found on resistors. Why reinvent things if I don’t have to. So here is how I solved this problems.

So let now see how this works out —

Here is the layout of the color coding for these sensors located in tower tube –

Here is the layout of the color coding for these sensors located in tower tube –

Temp Probes are – BLUE color

Water Probes are – YELLOW color

Start the code at the Sensor position and work into the inter-core

These patterns are repeated on both ends of the cable with the outer most position being the sensor color. So if you held the two ends up together with the connectors facing the same direction then the code would mirror each other.

agponic Tower — interface plates — 3 different templates needed November 12, 2013

Posted by rik94566 in agponics.com, aquaponic automation, aquaponics, aquaponics electronics, arduino, DIY aquaponics, Interface Plate, Internet-of-Farming, IoT aquaponics, sensor, Tower System.Tags: automation, Controlled Environment Agriculture, DIY aquaponics, indoor aquaponics, rik kretzinger, sensor

2 comments

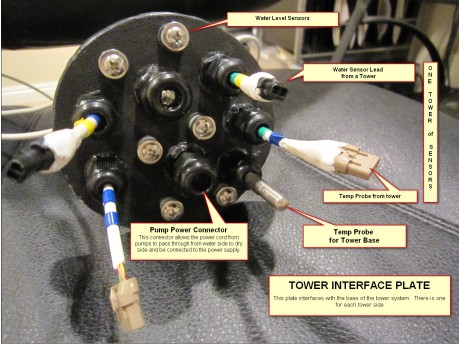

To build the tower base with all the sensors a interface plate is needed to prevent water from reaching the inter core of the tower base. As it turns out 3 different templates are needed to accomplish the task.

Here is what one looks like once it is completed and ready to be installed into a tower base:

TOWER CORE GUTS – now for sale in “Things for sale” page September 26, 2013

Posted by rik94566 in agponics.com, aquaponic automation, aquaponics, aquaponics electronics, Internet-of-Farming, IoT aquaponics, Tower System, Tower Tubes, Tube Guts.Tags: aquaponic automation, DIY aquaponics, DS18B20, indoor aquaponics, microcontroller, rik kretzinger, sensor, Temperature Probe

5 comments

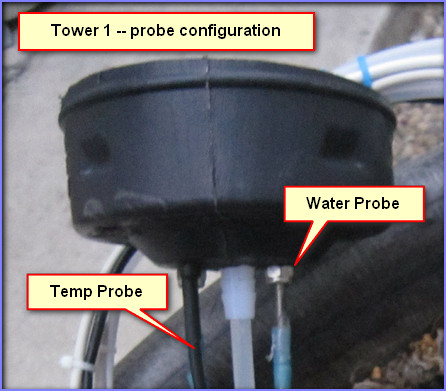

Here is what goes into the Tower Tubes and provides the water to the top and wiring for the sensor. The sensor configuration is a “Water Sensor” and “Temp Prob” combination. These have waterproof connectors that can be disconnected when the towers are removed to be taken to market or needing media to be pulled out once a crop is spent.

TOWER INTERFACE PLATE — protects the dry core of the tower base September 25, 2013

Posted by rik94566 in agponics.com, aquaponics, DIY aquaponics, DS18B20, Hacks, Interface Plate, One-wire, Sensor Hub, Tower System.Tags: 1-wire, aquaponic automation, DIY aquaponics, DS18B20, microcontroller, rik kretzinger

add a comment

Here is the “INTERFACE PLATE” — this plate is inserted into the base of the towers and is sealed. With this interface plate in place wires can be run to tower sensors and power supplied to the pumps that feed the towers. Without these interface plates it would be dangerous to provide power to pumps or connect or disconnect the tower columns.