TIME TO STEP UP TO A BETTER TESTER March 21, 2021

Posted by rik94566 in aquaponic systems, aquaponics, Controlled Environment Agriculture, DIY aquaponics, general, Internet-of-Farming, IoT aquaponics, pH, rik kretzinger, rik.diy.IOT, rik94566.Tags: aquaponics, Bluelab, pH, rik-dyi-IOT, rik94566, tester

add a comment

For about 3 years I have been using a cheap pH tester. The main reason for using cheap units has been that I did not know the type and configuration that I wanted to purchase for the main unit that I would be using for many years to come. After the purchase of another testing probe made by Bluelab I started researching the pH options the Bluelab offered. As I found many different units that could be purchased for this purpose. So after some time and reading many reviews I selected the pH-PEN. Life has gotten much simpler with this purchase. More expensive YES – but I now save so much time as the calibration holds for a month and is very accurate every time I use the unit. So happy I selected this unit of very high quality and perfect for all my needs. I purchased the unit from Amazon.

HOME ASSISTANT — NODE-RED August 31, 2020

Posted by rik94566 in agponics.com, aquaponic automation, aquaponic systems, aquaponics, auqaponics automation, Controlled Environment Agriculture, DIY aquaponics, indoor aquaponics, internet of farming, Internet-of-Farming, Uncategorized.Tags: aquaponic automation, aquaponic devices, Home Assistant, Internet-of-Farming, Node-Red, rik kretzinger, rik-dyi-IOT, rik94566

add a comment

Researching how best to start learning Node-Red I spent a lot of time on YouTube watching what Node-Red is and how people learned how to use it. As always a lot of YouTuber’s put out content and some are clearly better at actually helping people understand concepts and produce valuable content that can be put to use by a non-computer programmer type person.

So I developed my list of people that were best for me to follow and start the process of learning this new skill set. Many of the ones I like were talking about the use of Node-Red with Home Assistant.

I had looked at Home Assistant some years ago and at the time it seemed Home Assistant was for very advanced users that are very good at the command prompt and with a lot of system knowledge. Way above my level at the time.

Then my research turned up this reference and changed my perspective on using Home Assistant.

This was, just what I was looking for.

DS18B20 – Resistor Module – parts defined November 4, 2019

Posted by rik94566 in 1-wire, agponics.com, aquaponic devices, aquaponics electronics, auqaponics automation, DIY aquaponics, DS18B20, ds18b20, Electronic Componets, indoor aquaponics, internet of farming, Internet-of-Farming, IoT aquaponics, One-wire, rik kretzinger, rik.diy.IOT, rik94566.Tags: aquaponic automation, aquaponic devices, aquaponic electronics, aquaponic sensors, aquaponics, DS18B20, DS18B20 aquaponics, ds18b20 water proof, Internet-of-Farming, rik, rik-dyi-IOT, rik94566, sensors

6 comments

Working with the resistor module is making things much easier and a lot less work on my part. I am liking what I am seeing from a development standpoint and can see a real time savings that will deliver consistent results. First step is understanding what is found on the board and which end goes with which connection.

Been looking for a better way – DS18B20 October 15, 2019

Posted by rik94566 in 1-wire, agponics.com, aquaponic devices, aquaponics electronics, arduino, auqaponics automation, Balcony aquaponics, Balcony Garden, Controlled Environment Agriculture, DIY aquaponics, DS18B20, ds18b20, Electronic Componets, internet of farming, Internet-of-Farming, IoT aquaponics, rik kretzinger, rik.diy.IOT, rik94566, sensor, Stainless Steel Temp Probe, Temperature Probe.Tags: agponics, aquaponics, DIY aquaponics, DS18B20, DS18B20 aquaponics, Internet-of-Farming, rik, rik94566, sensor

3 comments

I was doing some research on a totally different subject and this popped up.

Why this one?

Well easy answer – I have been making my own 4.7 pull-up resistor connectors for sometime now. Problem for me is that they take a lot of time and are very bulky and hard to work with. For a little more cost a dollar or so I get a board that will allow easy connections to many (so I think) DS18B20 sensors using one resistor. The order came and now I can start testing my idea. Having a solution this turn key will save a lot of time and perform better, time will tell now.

I will be posting how the testing goes and what will be needed to get top performance out of this module.

Miniature Test Leads – which ones work best for my projects July 20, 2019

Posted by rik94566 in adafruit, agponics.com, aquaponic automation, aquaponic systems, DIY aquaponics, indoor aquaponics, Instructables, internet of farming, Internet-of-Farming, IoT aquaponics, rik kretzinger, rik.diy.IOT, rik94566.Tags: aquapnic devices, aquaponic system parts, aquaponics, DIY aquaponics, Internet-of-Farming, jameco electronics, rik, rik94566, sensor

add a comment

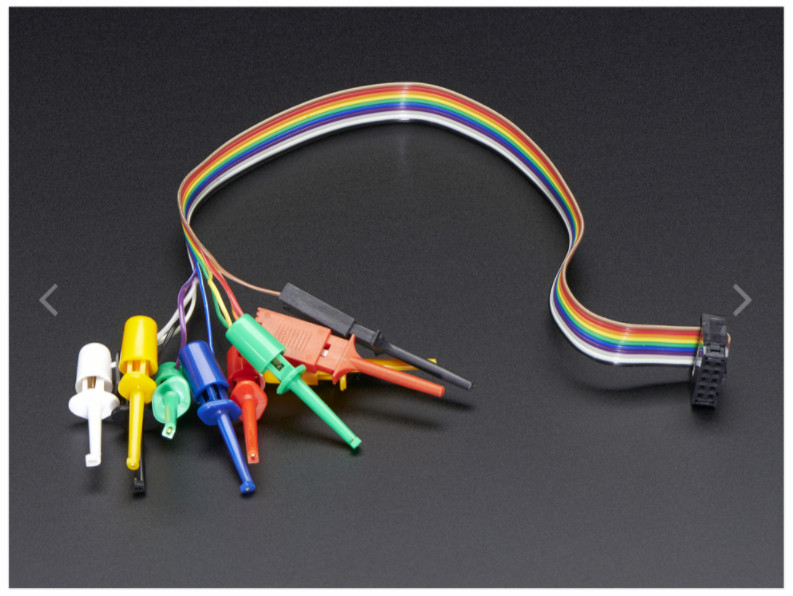

I wanted to move away from alligator clips because they were much large when working with small gauge wire. They did not work for me in very small areas. So was looking for a better solution. Found this miniature test leads at Jameco Electronics when I was picking up an order, they were a good solution for me.

When first using these miniature test leads they worked very well. But after a little time using these leads and problems surfaced. The problem was that they were cheaply made. The connection of the wire and the metal insert probe would break off without much stress placed on them. One or two is understandable, but 5 out of 10 was not the experience I was looking for.

When doing a search for a new product on the Adafruit site I found these test leads

These leads are a little larger than the Jameco test leads, but still were small enough for my use. Construction and connections were of high quality and work perfectly and held up with repeated use. So these are my new go to test leads for my development efforts. They will be seen in a number of up coming Instructables that I am working on and all my testing of sensors and connectors.

Temboo — aquaponic “HELLO WORLD” equivalent June 1, 2015

Posted by rik94566 in agponics.com, aquaponic automation, aquaponics, aquaponics electronics, Balcony aquaponics, internet of farming, Internet-of-Farming, rik94566.Tags: agponics, aquaponics, automation, balcony aquaponics, Controlled Environment Agriculture, DIY aquaponics, rik kretzinger, sensor, Temboo

add a comment

With the help of Temboo – my aquaponic Balcony Unit generated its first TEXT Message:

MESSAGE IS:

aquaponic Balcony Unit grow bed now filling.

Temboo – my new found friend May 28, 2015

Posted by rik94566 in aquaponic automation, aquaponics, arduino, Internet-of-Farming, Temboo.Tags: agponics, aquaponic automation, balcony aquaponics, rik kretzinger

add a comment

Ever since the release of the “Internet of Farming” YouTube interview – the recurring question is how to get the code working on my Arduino for my situation. Well — the reality of it is that everyone has a very different situation and totally different conditions specific to their setup and needs.

In the video I was using what was the best solution at the time to overcome this programming issue for me and what I was working to accomplish. I spent a lot of time on research and internet searches and came up with the best solution at the time. Fast forward 3 years and factor in advancements in technology and now things have progressed at a fast rate and new tools and companies are popping up in this next big area of technology growth IoT – Internet of Things.

I started learning about Temboo ( https://temboo.com/ ) on different blogs that I follow and checked them out and began to learn more about their solution. It seemed very simple in concept and very close to what I was looking for to help others on the same journey I have been on for a long time now. Couple this with the Balcony Unit I have been developing over the last year for entry level people wanting a solution to learn Aquaponics and use automation — it was a clear match. It is a match because if someone built a Balcony Unit for themselves or purchased a kit of parts then they can customize the software solution for their needs using Temboo. All I would have to do is supply a base code to get people started and then they can take their Balcony Units ( or other projects you have ) to whatever level you want. There you go a PERFECT WORLD!

So as it goes I contacted Temboo about working with me on the Balcony Unit and the article for MAKE Magazine that is schedule to run sometime in the Fall of this year. Well it turns out Temboo was interested in this effort and will be working with me to get some base code build that all of you will have access to right here for the Balcony Unit. John Sigmier of Temboo reached out to me and let me know Temboo was interest in this effort. So I will be blogging about all this effort now that we are close to pulling it all together for the finished Balcony Unit effort. You will be reading about this effort and what I learn in this process.

TOWER SYSTEM – set-up at Maker Faire 2014 May 22, 2014

Posted by rik94566 in adafruit, agponics.com, arduino, DIY aquaponics, DS18B20, Electronic Componets, indoor aquaponics, indoor gardens, indoor growing, Internet-of-Farming, IoT aquaponics, One-wire, Raspberry PI, Tower System, Tower Tubes.Tags: agponics, aquaponics, automation, Controlled Environment Agriculture, DIY aquaponics, indoor aquaponics, IoT, Maker Faire, microcontroller, rik kretzinger, sensor

2 comments

EDITOR’S CHOICE – not once – but 3 times @ Maker Faire – WOW May 21, 2014

Posted by rik94566 in agponics.com, aquaponic automation, aquaponics, aquaponics electronics, arduino, DIY aquaponics, indoor aquaponics, indoor gardens, indoor growing, Internet-of-Farming, IoT aquaponics, Raspberry PI, sensor, Tower System.Tags: aquaponic automation, aquaponics, automation, DIY aquaponics, indoor aquaponics, microcontroller, rik kretzinger

2 comments

Very few displays achieve 3 EDITOR CHOICE AWARDS —

RADIAL FLOW FILTER – just completed April 2, 2014

Posted by rik94566 in agponics.com, aquaponic automation, aquaponics, aquaponics electronics, Controlled Environment Agriculture, DIY aquaponics, Electronic Componets, indoor aquaponics, Internet-of-Farming, IoT aquaponics, PRODUCTS, radial flow filter, Tower System.Tags: aquaponic automation, automation, Controlled Environment Agriculture, DIY aquaponics, indoors aquaponics, IoT, microcontroller, rik kretzinger

add a comment

Since first conceiving of the Tower unit as a concept I knew they needed to be operated differently than DWC and Media bed in how you deal with the solids from the fish. Media beds — it has not been that big a deal for me because my rule is that any tank size smaller than 350 I filter the water and break-up the solids and then put back into solution by pumping back into the grow beds. This way I lose no nutrients that the fish produce. Has worked well for over 3 years now. In the testing that I have done with the towers I found that solids need to be dealt with or things will plug up. I still will be reintroducing the broken up solids back into the system put it will take place downstream of the bio-filter component and re-injected into the new buffer tank that stabilizes fish tank water volume and height. This all came out of research I was doing on how best to handle solids in aquaponics. As designed this radial flow filter can handle up to and maybe a bit more than a 1000 gallons of fish tank water. The only thing left to figure out on this radial flow filter now is where I will be locating the outlet for the clean water. That will be dependent on fish tank water level. Should have fish tank completed this coming weekend and make the determination on this aspect of the build.

Since first conceiving of the Tower unit as a concept I knew they needed to be operated differently than DWC and Media bed in how you deal with the solids from the fish. Media beds — it has not been that big a deal for me because my rule is that any tank size smaller than 350 I filter the water and break-up the solids and then put back into solution by pumping back into the grow beds. This way I lose no nutrients that the fish produce. Has worked well for over 3 years now. In the testing that I have done with the towers I found that solids need to be dealt with or things will plug up. I still will be reintroducing the broken up solids back into the system put it will take place downstream of the bio-filter component and re-injected into the new buffer tank that stabilizes fish tank water volume and height. This all came out of research I was doing on how best to handle solids in aquaponics. As designed this radial flow filter can handle up to and maybe a bit more than a 1000 gallons of fish tank water. The only thing left to figure out on this radial flow filter now is where I will be locating the outlet for the clean water. That will be dependent on fish tank water level. Should have fish tank completed this coming weekend and make the determination on this aspect of the build.

I put together a youtube slide show if you want to see more detail of the radial flow filter: