DS18B20 – Resistor Module – parts defined November 4, 2019

Posted by rik94566 in 1-wire, agponics.com, aquaponic devices, aquaponics electronics, auqaponics automation, DIY aquaponics, DS18B20, ds18b20, Electronic Componets, indoor aquaponics, internet of farming, Internet-of-Farming, IoT aquaponics, One-wire, rik kretzinger, rik.diy.IOT, rik94566.Tags: aquaponic automation, aquaponic devices, aquaponic electronics, aquaponic sensors, aquaponics, DS18B20, DS18B20 aquaponics, ds18b20 water proof, Internet-of-Farming, rik, rik-dyi-IOT, rik94566, sensors

6 comments

Working with the resistor module is making things much easier and a lot less work on my part. I am liking what I am seeing from a development standpoint and can see a real time savings that will deliver consistent results. First step is understanding what is found on the board and which end goes with which connection.

Been looking for a better way – DS18B20 October 15, 2019

Posted by rik94566 in 1-wire, agponics.com, aquaponic devices, aquaponics electronics, arduino, auqaponics automation, Balcony aquaponics, Balcony Garden, Controlled Environment Agriculture, DIY aquaponics, DS18B20, ds18b20, Electronic Componets, internet of farming, Internet-of-Farming, IoT aquaponics, rik kretzinger, rik.diy.IOT, rik94566, sensor, Stainless Steel Temp Probe, Temperature Probe.Tags: agponics, aquaponics, DIY aquaponics, DS18B20, DS18B20 aquaponics, Internet-of-Farming, rik, rik94566, sensor

3 comments

I was doing some research on a totally different subject and this popped up.

Why this one?

Well easy answer – I have been making my own 4.7 pull-up resistor connectors for sometime now. Problem for me is that they take a lot of time and are very bulky and hard to work with. For a little more cost a dollar or so I get a board that will allow easy connections to many (so I think) DS18B20 sensors using one resistor. The order came and now I can start testing my idea. Having a solution this turn key will save a lot of time and perform better, time will tell now.

I will be posting how the testing goes and what will be needed to get top performance out of this module.

aquaponic- IoT device — Balcony Garden March 10, 2015

Posted by rik94566 in aquaponic automation, aquaponics, Balcony aquaponics, Controlled Environment Agriculture, DS18B20.Tags: agponics, aquaponic automation, aquaponics, arduino, automation, balcony aquaponics

add a comment

BALCONY AQUAPONIC GARDEN – IoT READY- DIY or purchase materials locally and build — by rik kretzinger

TOWER SYSTEM – set-up at Maker Faire 2014 May 22, 2014

Posted by rik94566 in adafruit, agponics.com, arduino, DIY aquaponics, DS18B20, Electronic Componets, indoor aquaponics, indoor gardens, indoor growing, Internet-of-Farming, IoT aquaponics, One-wire, Raspberry PI, Tower System, Tower Tubes.Tags: agponics, aquaponics, automation, Controlled Environment Agriculture, DIY aquaponics, indoor aquaponics, IoT, Maker Faire, microcontroller, rik kretzinger, sensor

2 comments

IT’S OFFICIAL – Maker Faire 2014 – we will be there with a booth to show case Tower unit March 24, 2014

Posted by rik94566 in adafruit, agponic MD, agponicMD, agponics.com, aquaponic automation, aquaponics, aquaponics electronics, arduino, DIY aquaponics, DS18B20, indoor aquaponics, Internet-of-Farming, IoT aquaponics, One-wire, PRODUCTS, sensor, Stainless Steel Temp Probe, Tower Pocket Block, Tower Tubes, Yourduino.Tags: aquaponic automation, arduino sketch, DIY aquaponics, indoor aquaponics, microcontroller, rik kretzinger

4 comments

IT’S OFFICIAL NOW:

I’ve been accepted to exhibit at @MakerFaire Bay Area on May 17 & 18, 2014 http://makerfaire.com/

#20475 – internet of farming arduino-based aquaponics

Will be able to show case a number of new leading edge things that I have been developing.

Here are just a few of them:

Design of a “Radial Flow Filter” for the tower unit system ( will be blogging and doing a Youtube video about it shortly”

Venturi DIY design that will replace air pumps on my systems.

Aquaponic Fog Unit that I have just completed and in testing mode now.

Have fully working Tower unit with totally enabled IoT features that show case the latest developments in this technology as related to aquaponics.

agponic-MD — features defined February 4, 2014

Posted by rik94566 in 1-wire, agponic MD, agponicMD, agponics.com, aquaponic automation, aquaponics, aquaponics electronics, DIY aquaponics, DS18B20, indoor aquaponics, indoor growing, Internet-of-Farming, IoT aquaponics, One-wire, PRODUCTS, Stainless Steel Temp Probe, Temperature Probe.Tags: 1-wire, aquaponic automation, automation, DIY aquaponics, DS18B20, indoor aquaponics, rik kretzinger, sensor, Temp Probe, Temperature Probe

2 comments

Now that the basic agponic-MD unit is completed – I am working through all the different features that can be found on the unit and define there functions.

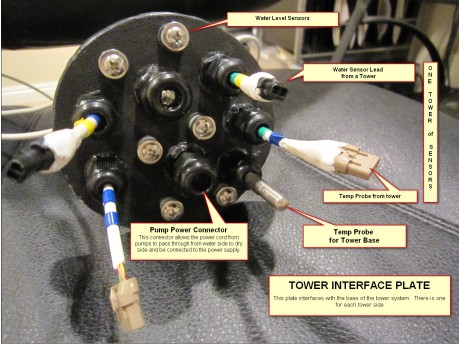

Here is one side of the connection box at the back of the unit.

Re-Design of agponic-MD January 29, 2014

Posted by rik94566 in agponic MD, agponicMD, agponics.com, aquaponic automation, aquaponics, aquaponics electronics, DS18B20, Float Sensor, Float Switch, indoor aquaponics, IoT aquaponics, One-wire.Tags: aquaponic automation, aquaponics, automation, CAT 5 cable, Controlled Environment Agriculture, DIY aquaponics, indoor aquaponics, microcontroller, rik kretzinger

2 comments

After much thinking about how I could improve the desktop aquaponic automation simulator called agponic-MD (micro-device) I built a new one. It helps to have people that wanted to purchase a few of them. So I got busy and made it a bit larger with expansion capability for future components like a 12V backup system and additional sensors to learn how to automate. Here is the feature set for the re-designed agponic-MD.

After much thinking about how I could improve the desktop aquaponic automation simulator called agponic-MD (micro-device) I built a new one. It helps to have people that wanted to purchase a few of them. So I got busy and made it a bit larger with expansion capability for future components like a 12V backup system and additional sensors to learn how to automate. Here is the feature set for the re-designed agponic-MD.

Fully valved for water movement and control

Large grow bed and tank configuration

4 – water level control sensors

1 – RH and temp internal probe

3 – temp probes (grow bed / water tank / outside)

1 – water flow sensor

1 – pH probe and connectors

1 – DO or additional probe expansion options for future growth of unit

1 – controllable drain port

1 – grow bed media package to fit grow bed (comes from an established grow bed – so bacteria included)

1 – Container of starter water from an active system ( should you like to cycle the system)

1 – outside tank temp indicator

1 – Heater for tank water

1 – Air pump and stone

Over flow configuration to prevent spillage in grow bed

SENSOR COLOR CODE – for tracking where the probes are in the towers December 9, 2013

Posted by rik94566 in agponics.com, aquaponic automation, aquaponics, Controlled Environment Agriculture, DIY aquaponics, DS18B20, IoT aquaponics, Tower System, Tower Tubes.Tags: aquaponic automation, aquaponic crop, DIY aquaponics, rik kretzinger, sensor

2 comments

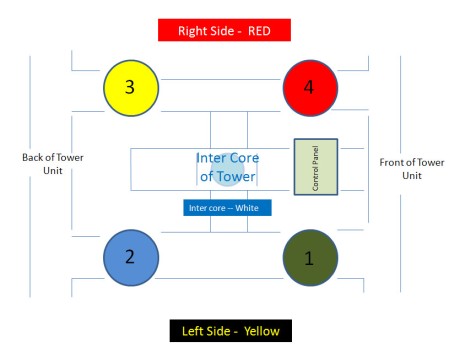

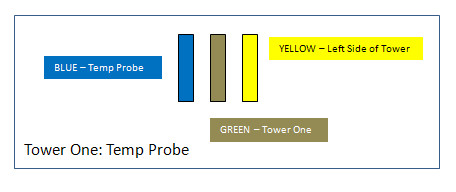

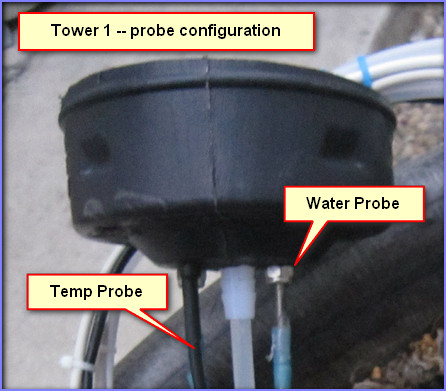

Since I have a larger number of sensors in each tower unit I needed a way to know the exact sensor I will be dealing with and the location of the sensor. The best way for me is to mimic the electronic color codes found on resistors. Why reinvent things if I don’t have to. So here is how I solved this problems.

So let now see how this works out —

Here is the layout of the color coding for these sensors located in tower tube –

Here is the layout of the color coding for these sensors located in tower tube –

Temp Probes are – BLUE color

Water Probes are – YELLOW color

Start the code at the Sensor position and work into the inter-core

These patterns are repeated on both ends of the cable with the outer most position being the sensor color. So if you held the two ends up together with the connectors facing the same direction then the code would mirror each other.

TOWER INTERFACE PLATE — protects the dry core of the tower base September 25, 2013

Posted by rik94566 in agponics.com, aquaponics, DIY aquaponics, DS18B20, Hacks, Interface Plate, One-wire, Sensor Hub, Tower System.Tags: 1-wire, aquaponic automation, DIY aquaponics, DS18B20, microcontroller, rik kretzinger

add a comment

Here is the “INTERFACE PLATE” — this plate is inserted into the base of the towers and is sealed. With this interface plate in place wires can be run to tower sensors and power supplied to the pumps that feed the towers. Without these interface plates it would be dangerous to provide power to pumps or connect or disconnect the tower columns.