ASPARAGUS – year 2 March 1, 2014

Posted by rik94566 in agponics.com, aquaponic automation, aquaponics, asparagus, Crop, DIY aquaponics, IoT aquaponics.Tags: aquaponic automation, aquaponic crop, DIY aquaponics, indoor aquaponics, microcontroller, rik kretzinger, sensor

add a comment

Well I am into year 2 with my asparagus. The weather in Northern California has been short on rain and very warm. So no surprise that my asparagus is about 2 months ahead of normal. I was thinking that it would be about a month earl as I can control almost all the environmental factors that impact the growth cycle. Just so happy to see that it survived the winter and growing well. You judge for yourself!

200,000 Views on Youtube – “Internet of Farming” — WOW February 2, 2014

Posted by rik94566 in agponics.com, aquaponic automation, aquaponics, Crop, DIY aquaponics, Internet-of-Farming, IoT aquaponics, Tower System.Tags: aquaponic crop, automation, Controlled Environment Agriculture, DIY aquaponics, indoor aquaponics, IoT, LED aquaponics, microcontroller, rik kretzinger, Temp Probe, Temperature Probe

add a comment

2013 in review December 31, 2013

Posted by rik94566 in agponics.com, aquaponic automation, aquaponics, aquaponics electronics, arduino, CEA, DIY aquaponics, Electronic Componets.Tags: aquaponic automation, aquaponic crop, CEA, DIY aquaponics, indoor aquaponics, microcontroller, rik kretzinger, sensor

add a comment

2013 annual report for aquaponic DIY Automation blog.

Here’s an excerpt:

The concert hall at the Sydney Opera House holds 2,700 people. This blog was viewed about 35,000 times in 2013. If it were a concert at Sydney Opera House, it would take about 13 sold-out performances for that many people to see it.

SENSOR COLOR CODE – for tracking where the probes are in the towers December 9, 2013

Posted by rik94566 in agponics.com, aquaponic automation, aquaponics, Controlled Environment Agriculture, DIY aquaponics, DS18B20, IoT aquaponics, Tower System, Tower Tubes.Tags: aquaponic automation, aquaponic crop, DIY aquaponics, rik kretzinger, sensor

2 comments

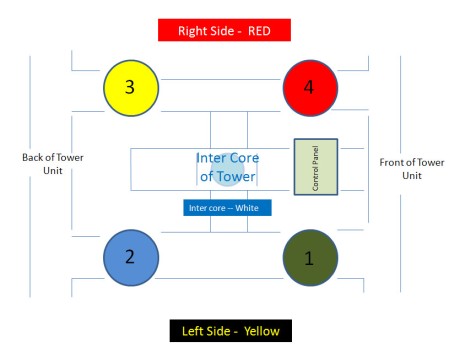

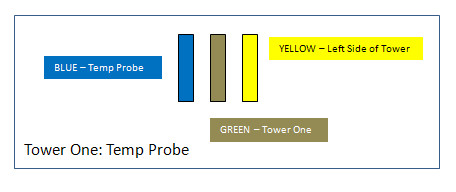

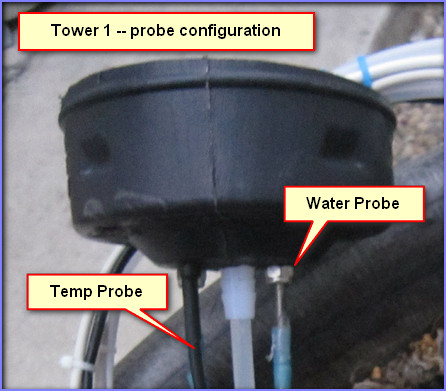

Since I have a larger number of sensors in each tower unit I needed a way to know the exact sensor I will be dealing with and the location of the sensor. The best way for me is to mimic the electronic color codes found on resistors. Why reinvent things if I don’t have to. So here is how I solved this problems.

So let now see how this works out —

Here is the layout of the color coding for these sensors located in tower tube –

Here is the layout of the color coding for these sensors located in tower tube –

Temp Probes are – BLUE color

Water Probes are – YELLOW color

Start the code at the Sensor position and work into the inter-core

These patterns are repeated on both ends of the cable with the outer most position being the sensor color. So if you held the two ends up together with the connectors facing the same direction then the code would mirror each other.

agponic MD — adding cable gland to the container November 12, 2013

Posted by rik94566 in agponic MD, agponics.com, aquaponics, DIY aquaponics, Internet-of-Farming, IoT aquaponics.Tags: aquaponic crop, container, DIY aquaponics, indoor aquaponics, rik kretzinger, sensor, tank container

add a comment

An important aspect to making the agponic MD unit work is making sure the containers are water tight. There are a large number of holes made to accommodate the many mounting screws and allow sensor wires to pass from the tank container and grow bed container. Without addressing this issue early on one will only encounter leaks and problems once the unit is together.

STEP ONE — The parts

STEP TWO — Mark where the hole should be before drilling

STEP THREE — prep to drill

This is a very important step, if you do not take extra careful steps you will crack the plastic with the drill bit and you will be starting over. Support is needed behind the plastic.

STEP FOUR — make the hole

STEP FIVE — assembly the parts in the hole

STEP SIX — test the install — important last step

ATOMIC RED — (daucus carota) – aquaponic carrots April 23, 2012

Posted by rik94566 in aquaponics, Atomic Red Carrots, Carrots, Kitazawa Seed Company.Tags: aquaponic crop, aquaponics, carrots, DIY aquaponics, rik kretzinger

add a comment

At the first of the new year I had open bed space and a packet of Atomic Red Carrots from Kitazawa Seeds. So guess what — I thought I would give them a try.

When I looked at the expected growth characteristics I was a little early on the germination range and the height would be about 2 feet in total. I use a whole package of seed and just mixed into my gravel – nothing special here. The seeds are very – very – very tiny. They did float at first and ended up on one end of the bed area. Once germination was accomplished I just moved the seedlings around until I got the spacing I thought would work. Having never worked with carrots before I had no idea what to expect.

Well as of this past weekend here is what I have:

Here are additional pictures to show how well these “ATOMIC REDS” are doing.

Akasanjaku – Yard Long Bean February 19, 2012

Posted by rik94566 in Akasanjaku, aquaponics, Kitazawa Seed Company, Yard Long Bean.Tags: Akasanjaku, aquaponic crop, DIY aquaponics, Kitazawa Seed, rik kretzinger, Yard Long Bean

add a comment

Akasanjaku

Vigna unguiculata subsp sesquipedalis

Akasanjaku

|

Seed #174 |  |

- Warm season annual

- Approx. 50-60 seeds in packet. (A seed will vary in weight and size within a given seed lot. The number of seeds stated is only an estimate.)

- Maturity: Approx. 75 days

- Planting season: Late spring to early summer

DS18B20 — external power supply December 15, 2011

Posted by rik94566 in 1-wire, aquaponic automation, aquaponics, arduino, CEA, Controlled Environment Agriculture, DIY aquaponics, DS18B20, HEX code, indoor aquaponics, indoor gardens, indoor growing, One-wire, probe index, sensor, Sensor Hub, Stainless Steel Temp Probe, Temperature Probe.Tags: 1-wire, aquaponic automation, aquaponic crop, arduino, arduino sketch, automation, CEA, Controlled Environment Agriculture, DIY aquaponics, DS18B20, electronics, indoor aquaponics, indoors aquaponics, microcontroller, rik kretzinger, sensor, Temp Probe, Temperature Probe

1 comment so far

Before I can connect everything up and work with my DS18B20 probes using external power supply I need to get one. The one that I have selected is this one:

DS18B20 – on to external power December 7, 2011

Posted by rik94566 in 1-wire, aquaponic automation, aquaponics, arduino, CEA, Controlled Environment Agriculture, DIY aquaponics, DS18B20, HEX code, indoor aquaponics, indoor gardens, indoor growing, One-wire, probe index, sensor, Sensor Hub, Stainless Steel Temp Probe, Temperature Probe.Tags: 1-wire, aquaponic automation, aquaponic crop, aquaponics, arduino, arduino sketch, automation, CEA, Controlled Environment Agriculture, DIY aquaponics, DS18B20, ds18b20 water proof, electronics, indoor aquaponics, microcontroller, rik kretzinger, sensor, Temp Probe, Temperature Probe, water proof temp probe

2 comments

When you want to learn something new in electronics, you have to start at the bottom. In my mind a circuit layout like this is the bottom for me and it is hard for me to follow. I will be the first to admit that I am not an electrical engineer and don’t want to be one either. I just want a simple way to hook things up and have them work when I need them too. So this layout just gives me a general idea of where to start on hooking up a external power source for my probes. I was at this same point when I started to learn about DS18B20’s and use with an arduino. The good news is that I have a more clear understanding how the DS18B20 functions and how it operates than when I first started on this project.

WHY DO I NEED EXTERNAL POWER FOR MY DS18B20’S ——-

Well that is a very good questions. In most applications and small projects you do not need to know anything about this aspect of the DS18B20’s. In my case as I have been working on this blog several questions have been posed as to power drains on arduino’s if you request to many sensors being driven by the unit and you have long runs to your sensors. So I need to do some research as to how to use a external power source. A lot of places on the internet talk about it, but I have yet to find any source that shows a person how to actually make this work. As for the research here is the best I could find. If you know of others please let me know and I will add it to my library and give you credit for it here.

HERE IS THE BIBLE ON THIS SUBJECT —

http://www.arduino.cc/playground/Learning/OneWire

Normal (external supply) mode

With an external supply, three wires are required: the bus wire, ground, and power. The 4.7k pull-up resistor is still required on the bus wire. As the bus is free for data transfer, the microcontroller can continually poll the state of a device doing a conversion. This way, a conversion request can finish as soon as the device reports being done, as opposed to having to wait 750ms in “parasite” power mode.

Note on resistors: For larger networks, you can try something smaller. The ATmega328/168 datasheet indicates starting at 1k6 and a number of users have found smaller to work better on larger networks.

THAT IS ALL THERE IS — in this bible. Not much of a help in my mind.

HERE IS THE OTHER THING I FOUND:

http://sheepdogguides.com/dst9parasitic.htm

Choosing your 1-Wire chip power mode

Many of the chips in the 1-Wire family from Dallas Semiconductor can be powered “parasitically”… that’s Dallas’s (apt) name for the system used.

The advantage of parasitic powering is that it means you can have a two wire MicroLan. (“MicroLan” is just Dallas’s trademarked name for a bunch of 1-Wire chips “playing nicely” with each other and a “master” device, e.g. a PC or simple microcontroller, e.g. Arduino, in charge of the network of 1-Wire sensors, actuators, storage units, etc.) If you don’t use parasitic powering, then you need to run three wires from chip to chip to chip. (An aside: You should be aware that MicroLans don’t like star topographies. If you need a star, you need a hub to split it into separate, non- star, legs.)

I’ve often used parasitic powering entirely successfully. However, if you have a lot of chips on the MicroLan, or high poll rates, the time may come when supplying the chips which can be powered parasitically makes sense. It isn’t difficult… especially if you provided for the possibility that you’d like to make the change when you first set up your MicroLan.

For example…

Just as an example, let’s consider a MicroLan that is reading temperatures in various parts of a large greenhouse.

We’ll assume you’re using chips from the DS182x family, in a TO92 package, the little blob of plastic with three “legs”.

To use those chips parasitically, you just connect two of the legs to one another, and that leaves you with two connections which go to the two wires of the basic MicroLan.

Now… and this is what I meant about giving yourself options for the future… rather than doing that the “obvious” way, using either a small PCB, or simple discrete wires, connect each of the three pins to a separate track or wire, and THEN make your connections to the MicroLan. If later, you want to use non parasitic power, then all you have to do is change a link, or disconnect one of the wires, and you can then supply the chip with its independent V,cc easily, without disturbing what would be fiddly connections to the package’s pins.

Here are the details of which pin is which on the DS1820…

The DS1820’s middle leg goes to the 1-Wire data line.

The DS1820’s leg marked “See text” should be attached to the 5v, or, for parasitic power, connect this pin to ground (zero volts))

And the DS1820’s “1-Wire 0v” should be attached ground,i.e. to zero volts.

(If the above seems over-explained, please remember that this page may be accessed by people who want more than just an idea of what this “parasitic power” thing is all about.)

AND THE LAST ONE I FOUND:

http://forums.parallax.com/showthread.php?135523-ds18b20-sensor-fails-at-high-temperature

- osts

- 117

Re: ds18b20 sensor fails at high temperature

Re: ds18b20 sensor fails at high temperature

I may have stumbled on a possible solution, but I am not sure how to code it. The snippet below is from the Maxim data sheet for the ds18b20. If I understand the second paragraph, correctly, I may need to Insert these commands:

Skip rom (cch)

Read power (b4h)

Then initiate a “read time slot”I am not sure how or where to insert these commands in the one wire object.

I am using an external power supply with a 4.7k pullup“The use of parasite power is not recommended for temperatures above +100°C since the DS18B20 may not be able to sustain communications due to the higher leakage currents that can exist at these temperatures. For applications in which such temperatures are likely, it is strongly recommended that the DS18B20 be powered by an external power supply.

In some situations the bus master may not know whether the DS18B20s on the bus are parasite powered or powered by external supplies. The master needs this information to determine if the strong bus pullup should be used during temperature conversions. To get this information, the master can issue a Skip ROM [CCh] command followed by a Read Power Supply [B4h] command followed by a “read time slot”. During the read time slot, parasite powered DS18B20s will pull the bus low, and externally powered DS18B20s will let the bus remain high. If the bus is pulled low, the master knows that it must supply the strong pullup on the 1-Wire bus during temperature conversions.

Not a lot to work with here, but I do have a lay out and now need to assemble the components I will need to pull this off. Don’t you just love electronics and all the neat stuff you get to learn!!!!